Analytical Testing Services

Product development is not possible without the ability to quantify minute changes in formulation characteristics.

By pairing product development with our wide range of analytical capabilities our team is able to help you find the answer to a variety of complex questions such as the effective concentration of preservatives, active ingredients, inert ingredients and stabilizers. Outsourcing your analysis to EcoSafe means that you’ll have access to a wide range of sophisticated instrumentation and testing methods. Consult with our team to find out how our analytical testing services, including formulation and comparative deformulation services, can be customized to fit your needs.

Some ways our analytical team can help you

Comparative Deformulation - Chemical reverse engineering and deformulation analysis to determine potential patent infringements, improve on existing products, or identify unknown ingredients in a competitors product.

Method Development or Validation - Our analytical team can help you develop accurate, reproduceable and reliable analytical techniques to measure the identity, purity or physical characteristics of the ingredients in your product. Our validation services are established based on the framework of your registration strategy.

Failure Analysis - Using a wide range of analytical techniques, our scientists can help you determine the root cause behind a product failure such as oversaturation, contamination, oxidation, or separation. Once we’ve identified the problem, our team can provide solutions and recommendations to prevent the failure from occurring in future batches.

Product Characterization and Analysis - Our testing laboratory is capable of characterizing a wide range of materials, including the identification of any impurities or other physical properties that might affect the performance of your formulation.

A sample of our analytical capabilities includes

Gas chromatography with mass spectral or Flame Ionization detection (GC-MS/FID) for the determination of the chemical composition of test substances and structure verification of active ingredients

High performance liquid chromatography – a softer technique for analysis of compounds that would be labile under GC conditions

Storage stability testing under warehouse (ambient) as well as temperature and humidity controlled accelerated storage conditions

Physical properties such as: pH, Density, Conductivity, Viscosity, Flammability, UV/Visible Absorption, Color, Odor, and Surface Tension

Moisture content analysis using Karl Fischer titration (liquids) or moisture balance (solids)

Vapor pressure analysis of all types of liquid such as gasoline, crude oil, solvents, fragrances and polymers

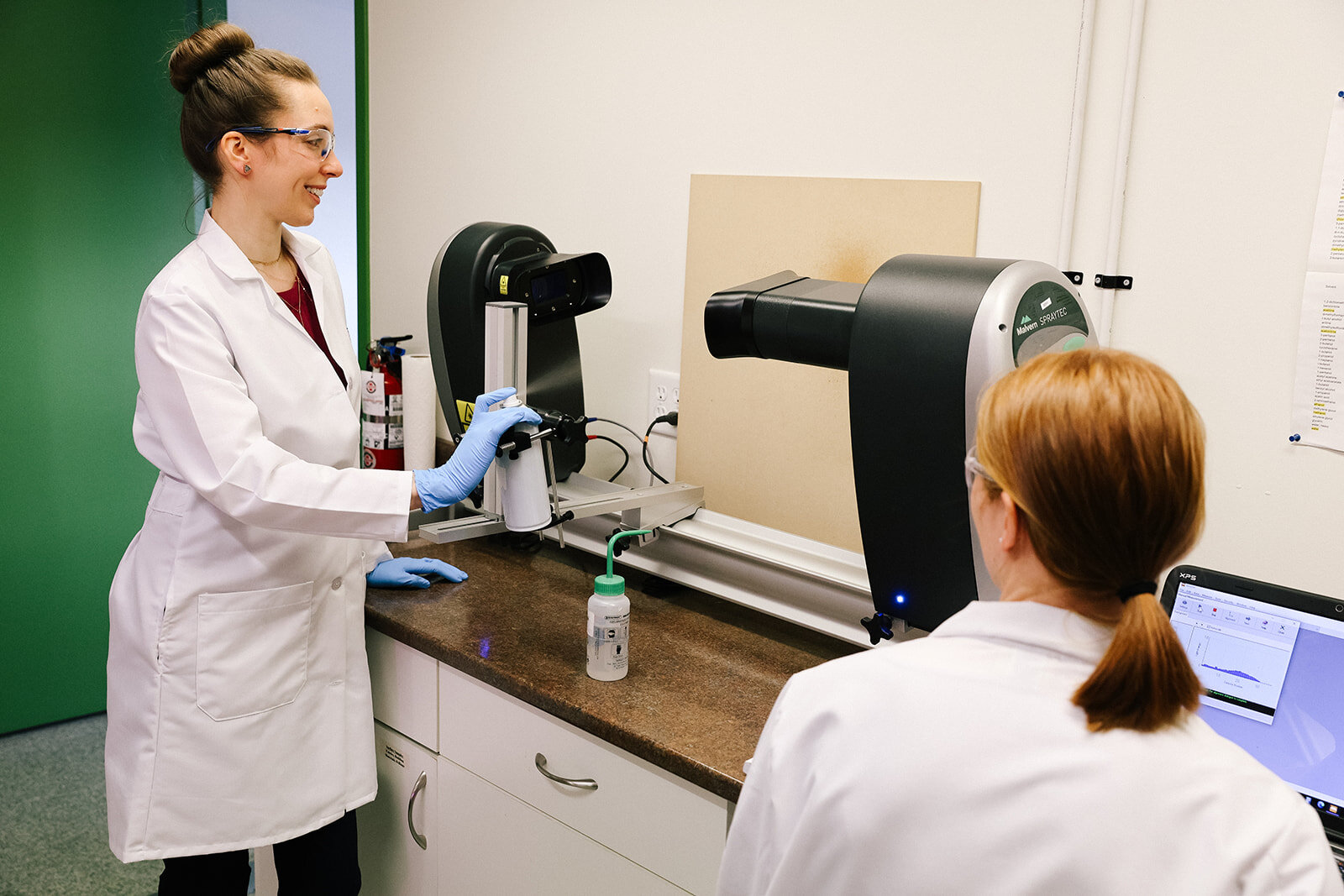

Particle size, droplet and spray pattern analysis of aerosols using our Spraytec laser diffraction spray particle size analyzer

Particle size analysis of liquids and solids down to 0.02 microns with our Malvern Lasersizer

Separation and identification of impurities or active ingredients using Flash Chromatography

Melting point (solids) and boiling point (liquids) of a broad range of materials for the determination of product purity and safety

Related Support Services

Find out how our approach can fit your needs